Lock

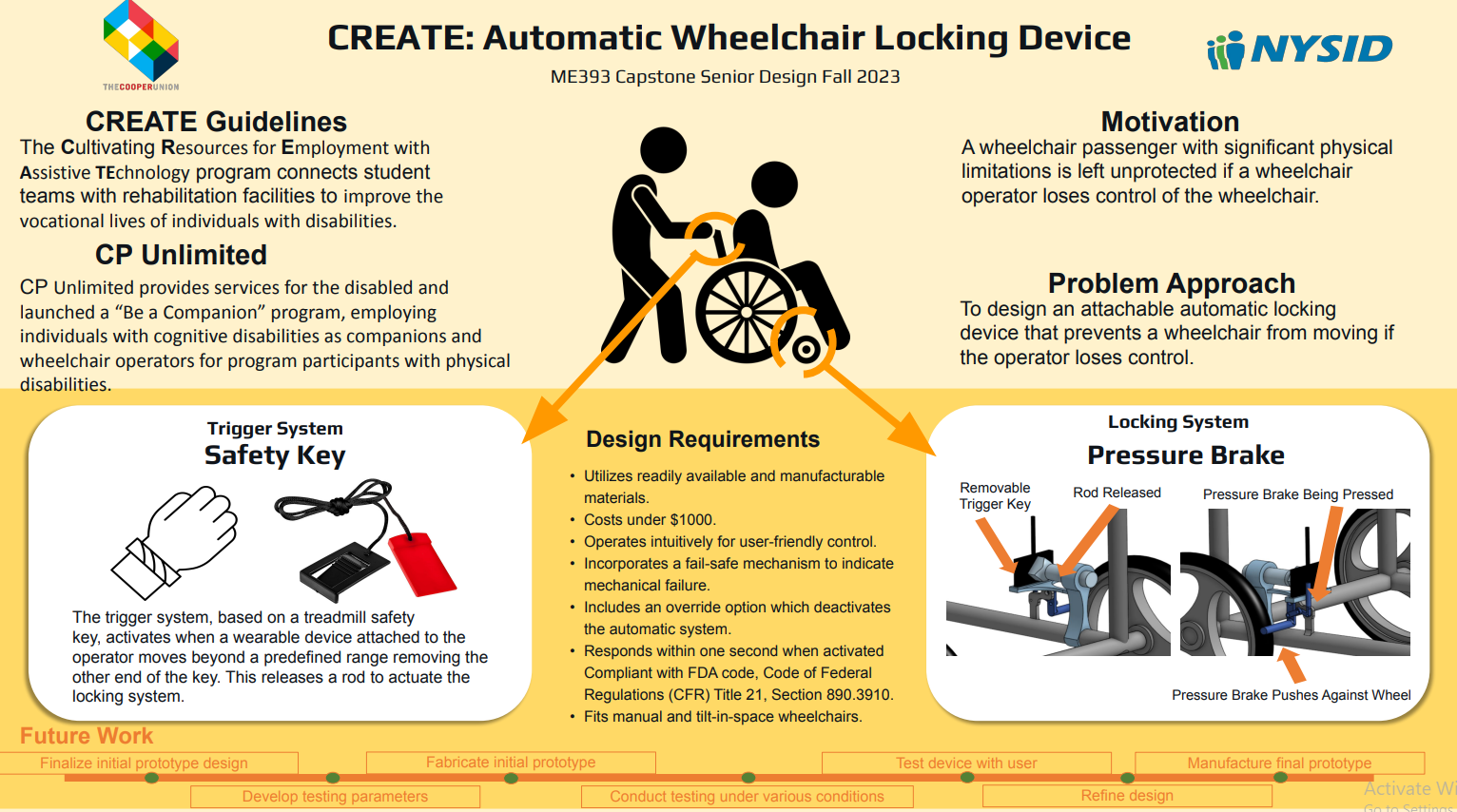

Lock is a project we've developed in collaboration with the New York State Industry for the Disabled (NYSID) under their CREATE program, which stands for "Cultivating resources for employment with Assistive Technology." This program connects students with rehabilitation facilities, aiming to improve the vocational lives of individuals with disabilities.

Our project began with visits to several facilities, leading us to partner with CP Unlimited, an organization that focuses on caring for the disabled through various medical, educational and recreational services. CP Unlimited recently launched a “Be a Companion” program, employing individuals with disabilities as companions and wheelchair operators at the Caldwell Group Home.

We identified a significant safety issue at this home: the manual wheelchairs lack an emergency stopping mechanism. This poses a risk for both the operators and the individuals they assist, especially in urgent situations.

To address this, we are developing an attachable automatic locking system for manual wheelchairs. This system will enable a safe and immediate stop in emergencies, enhancing the safety for both wheelchair operators and residents.

TIMELINE

August 2023 - Current

ROLE

User Research, CAD Design

PROBLEM

Manual wheelchairs lack an emergency stopping mechanism

A lack of an emergency stopping system poses risks for both the operators and the individuals they assist, especially in urgent situations.

SOLUTION

Attachable automatic locking mechanism

activates when a wearable device attached to the operator moves beyond a predefined range, removing the other end of the key.

Activation of the Safety Key releases a rod to actuate the locking system.

USER INTERVIEWS

The pressure brake is activated when the rod is released and pushes on the brake's lever.

The brake pushes a rod into the wheelchair's wheels, putting pressure on the tire which prevents the wheel from moving.

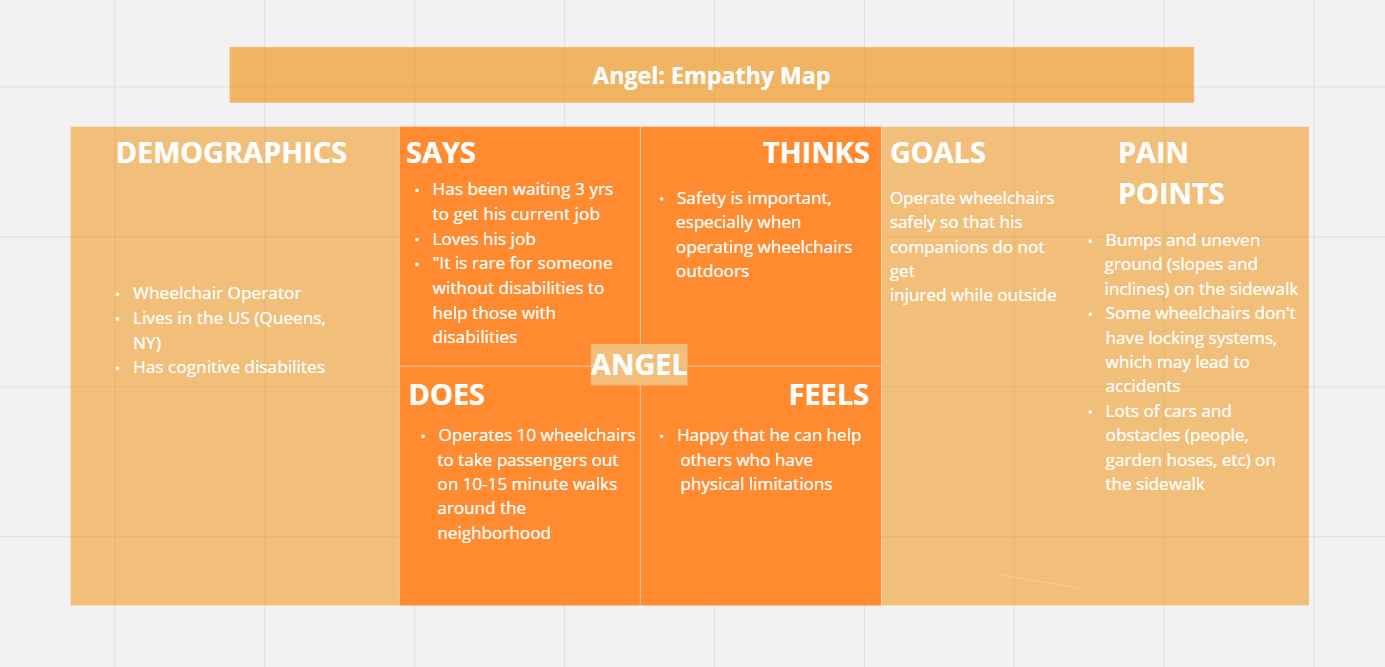

Interview with Client (Wheelchair Operator)

Starting with an interview with our client Angel, who is a wheelchair operator at the Caldwell Home, I began to identify his needs and paint points.

RESEARCH QUESTIONS:

Experience and Daily Routine:

- How often will you be pushing the wheelchair on a typical day?

- What types of environments (e.g., indoors, outdoors, uneven surfaces) do you think you’ll be usually encountering?

Current Challenges:

- Can you describe any difficulties you face when pushing the wheelchair?

- Are there specific situations or locations where it's more challenging to push the wheelchair?

Safety Concerns:

- Have you encountered any safety issues while pushing the wheelchair?

- Can you walk me through how you would stop the wheelchair, especially in an emergency?

Physical Strain:

- Do you experience any physical strain or discomfort while pushing the wheelchair? Can you tell me more about that?

- Are there any design changes that could make pushing the wheelchair more comfortable for you?

“I’m worried that I might lose grip of the wheelchair in unexpected emergency situations. If that happens and the passenger gets hurt, I’ll lose my job” -Angel

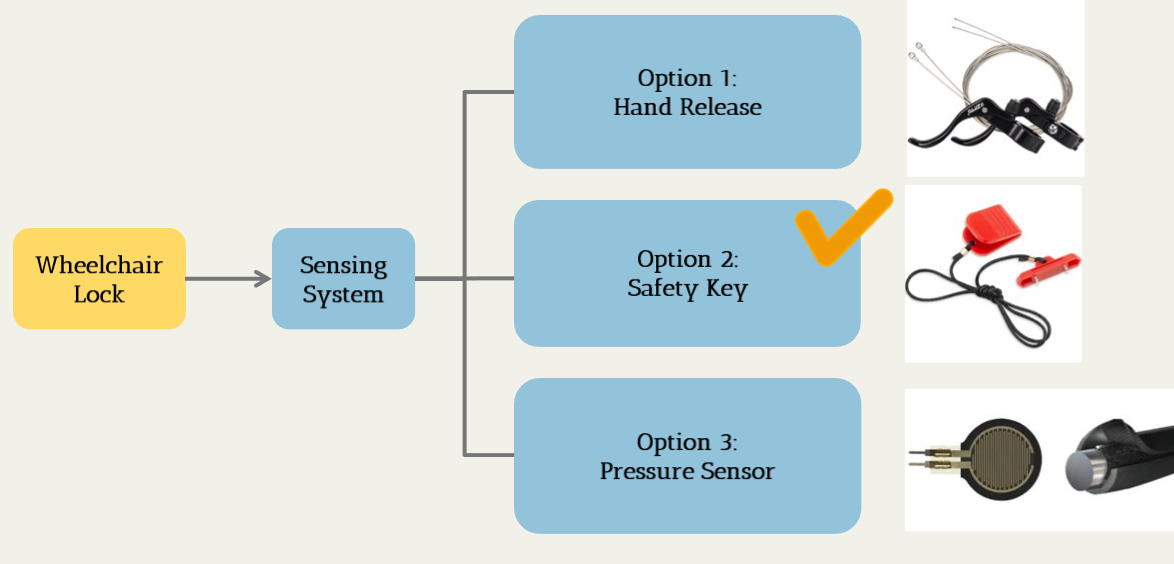

BRAINSTORMING

Sensing + Triggering + Locking

We pulled inspiration from real-world automatic locking systems.

The first idea is a hand-release brake similar to the airport luggage carts which you have to hold down in order to unlock the wheels. The second follows the treadmill safety key which stops the treadmill from moving when the magnet is removed from the control board if the user is too far from the unit. The third is an electric pressure brake which would detect if the operator lets go by the change in pressure.

We chose the treadmill key because of its easy override options, there are readily available materials that we can use, and it is durable in many weather conditions.

We chose to go with a mechanical trigger, as we are mechanical engineers and do not have the skillsets to create an electrical trigger or connect the system to a remote control.

We decided to go with a pressure lock for the locking system as it is easy to implement (by attaching a trigger system to the current locking system)

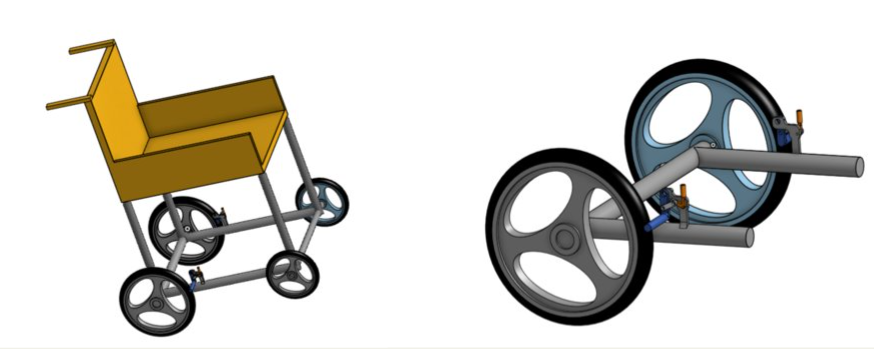

FIRST PROTOTYPE

Sensing -> Triggering -> Activating

The first prototype incorporates a modified treadmill clip as the sensing and trigger system which activates when the wearable device attached to the operator moves beyond a predefined range. This removes the other end of the key placed near the wheelchair’s built-in locking system. The removed key allows a rod to release and actuate the locking system by pressing on the pressure brake’s lever. This presses a bar into the wheelchair's tire exerting a controlled pressure that prevents the wheel from moving and locks the chair in place.

TESTING

Real World Scenarios

Real-world scenarios are key to the testing strategy. Situations where an operator might lose control of the wheelchair, such as during sudden stops or turns, are created to evaluate the effectiveness of the device in preventing accidents. The inclusion of wheelchair users with varying needs in these tests is essential to ensure the device’s usability.

The durability and reliability of the mechanism will be tested. Tests will be designed to simulate conditions of extended use, aiming to see how well the device withstands regular wear and tear. This is crucial for ensuring that the device maintains its functionality and reliability over time.

The adjustability and compatibility of the device with various wheelchair models is another vital aspect. The device will be evaluated on how easily it is attached and detached from different wheelchairs without modifications or special tools.

User Testing

Feedback from the user will be collected regularly throughout the process (once after each set of modifications) and improvements will be made to the design based on the feedback. Once preliminary testing is complete, trials involving the wheelchair operator and wheelchair passengers will be run to gather feedback on the usability and comfort of the locking mechanism. The impact of the device on the maneuverability of the wheelchair and the comforts of the users will be assessed, ensuring that the device enhances safety of the users without sacrificing usability.

Detailed documentation of all testing phases, results, and modifications will be kept, as this will be important for maintaining transparency and accountability.

FUTURE WORK

Testing + Improvements

The overall testing plan will consist of a series of tests that will evaluate the overall performance of a current design. The testing plan will be dependent on factors unrelated to any individual design, so that it could be used as a metric to evaluate and compare current, previous, and future design choices and prototypes. Metrics in the testing plan will include safety, efficiency, performance, durability and will be conducted at different angled surfaces.

To test for safety and performance, testing will keep track of three main parameters, fail-rate, lock time, and critical failure percentage. Fail-rate will be the percentage of time the design fails to properly lock. Lock time will be the time that it takes for the wheelchair to break from the instance the safety key is pulled. Critical failure percentage will consist of the percentage that the prototype’s locking mechanism causes the wheelchair to tip over and ultimately critically fail. The critical failures differ from regular failures as critical failures occur when the prototype causes the wheelchair additional damage because of tipping over, while regular failures are just situations when the design fails to stop the wheelchair from movement. This difference is essential in testing as critical failures are situations when the design worsens the problem instead of fixing it, while regular failures just happen to not stop the problem from occurring.

To test for durability, a series of tests will be done to simulate if the design can withstand usage for 3-5 years. Due to this project’s deadline occurring in under a year, true extensive durability tests lasting years cannot be conducted, however a simulation of a 3–5-year period can be conducted. To simulate this 3–5-year period, durability tests will be conducted by using the device the number of times it would be projected to be used in a 3-5 year period. To test for durability metric of a 3–5-year period, a combination of material analysis, projected usage, and tests that “damage” the prototype will be evaluated.

To test for efficiency, testing will consist of the transition period and how easily switchable the device is from one wheelchair to the other. The transition period consists of the time it takes to reset the device after usage. If it is painful and takes a long time to reset the device after every usage, the device may not be so efficient for a daily user. To test for these metrics, usage tests will be conducted.

In addition to the overall testing plan, other ideas will be evaluated as potential improvements to the design. These ideas will consist of both upgrades to the current design and improvements by replacing core components of the design for other avenues. One question that will be included in this analysis will be investigating whether locking both wheels will be more effective than one wheel. This idea can be done by either expanding the design to lock both wheels at the same time or comparing the current pressure lock prototype with a wheel hub system to determine which has the most effective dual-wheel activation locking. After hypothesizing on improvements, updated designs based on the improvements will be evaluated against previous designs based on the testing plan and logistical methods.